Discover the Perks of Making Use Of a stretch wrapping machine for Efficient Packaging Solutions

Automation has actually brought forth considerable developments, such as the stretch wrapping machine. What makes these machines a game-changer in the packaging industry?

Comprehending the Performance of Stretch Wrapping Machines

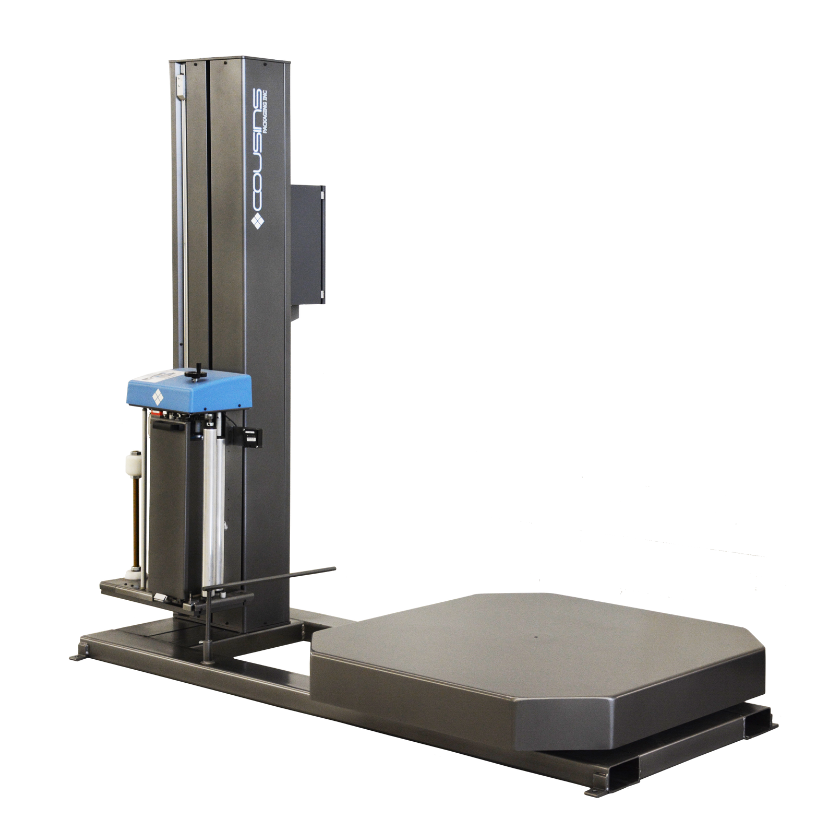

Originating the packaging industry, stretch wrapping makers enhance the process of firmly packaging products for transport or storage. These innovative makers utilize a straightforward yet reliable system, utilizing a stretchable plastic movie that is twisted around products, providing security and defense. The things, commonly arranged on a pallet, are rotated as the movie is given, ensuring a safe and secure and tight wrap.

The movie's flexibility serves a twin purpose: it securely binds the items together, minimizing the danger of damages due to motion, and it provides a barrier versus dirt, dampness, and various other possible unsafe components. In addition, the clear nature of the stretch movie enables simple identification of the packaged products.

The devices differ in their operation setting, with some being semi-automatic, needing marginal human intervention, and others being completely automatic, with the ability of individually handling the entire wrapping procedure. No matter their setting, stretch covering devices are a cornerstone of secure and efficient packaging.

How Stretch Covering Machines Enhance Performance

Boosting performance degrees significantly, stretch covering makers improve the packaging procedure with their automated capacities. These advanced makers enable companies to wrap a high volume of bundles rapidly and efficiently, providing a regular wrapping result that manual techniques merely can not match. This speed and uniformity translate directly right into increased performance, enabling businesses to satisfy requiring supply routines and consumer expectations.

Furthermore, stretch covering equipments call for very little human intervention. When the equipment is established up and the covering specifications are set up, the equipment can operate separately, freeing up workers to focus on various other essential tasks. This automation not only minimizes labor prices but additionally eliminates human errors, making certain the quality of covering remains constant.

Furthermore, using stretch wrapping machines usually results in less downtime. stretch wrapping machine. With their durable layout and reputable operation, these devices are much less prone to malfunctions and upkeep issues, making certain undisturbed process and boosted productivity

Decreasing Material Waste With Stretch Wrapping Machines

While enhancing efficiency, stretch covering makers likewise play a crucial function in decreasing product waste. The precision of these devices makes certain that each bundle is wrapped with the precise quantity of product required, lessening excess waste. This precision not just causes a visually pleasing and consistent package, however additionally adds considerably to ecological sustainability.

Essentially, the application of stretch covering makers in a product packaging line is not only an action in the direction of effective performance, yet also a jump in the direction of environment-friendly practices by significantly decreasing product waste.

Price Reduction: A Trick Advantage of Stretch Covering Machines

Along with mitigating product waste, another significant advantage of stretch covering devices is their possibility for price decrease. These equipments are reliable, requiring less manual work for product packaging products, consequently reducing down on labor prices.

Furthermore, stretch wrapping makers utilize much less product to package items safely as compared to standard wrapping methods. This reliable use materials not only reduces waste yet additionally decreases expense on product packaging materials.

The devices also decrease damages to products during transport. With protected and tough product packaging, the risk of product damage reductions, lowering the expenses related to product returns and substitutes.

Finally, the speed and performance of stretch covering makers can raise manufacturing rates. Faster packaging times imply that services can package and deliver more items in less time, boosting general performance.

Applying Stretch Wrapping Machines in Your Product Packaging Process

Offered the excellent benefits of stretch covering machines, integrating them into your packaging procedure can be a game-changing choice. An assessment of the existing product packaging process is required to establish the ideal device type and size.

Educating personnel on equipment operation is important. This consists of comprehending the maker's functionalities, repairing typical issues, and adhering to security guidelines. By doing so, organizations can make sure an efficient, affordable packaging procedure, reaping the full benefits of their investment in stretch wrapping equipments.

Verdict

To conclude, stretch wrapping makers use efficient, economical product packaging solutions. They improve performance and reduce waste by exactly wrapping products with stretchable plastic film, meeting high-volume needs with convenience. These machines make sure item security and defense, while also providing visually pleasing plans. For companies intending to optimize their product packaging procedures, this click to read more modern technology gives a reliable path towards improved effectiveness and cost financial savings.

Once the maker is set up and the covering parameters are set up, the maker can he has a good point run separately, releasing up staff members to focus on other vital jobs.While boosting productivity, stretch wrapping devices additionally play an essential role in decreasing product waste.Offered the outstanding benefits of stretch covering equipments, including them right into your product packaging procedure can be a game-changing decision - stretch wrapping machine. By doing so, companies can make certain an efficient, affordable packaging procedure, enjoying the complete benefits of their financial investment in stretch wrapping equipments

In conclusion, stretch wrapping devices supply effective, economical packaging remedies.